The challenge of racing against time

When an elevator breaks down, elevator maintenance personnel must rush to the customer's site for maintenance. The long-standing maintenance process is that when a failure occurs and needs to be repaired, maintenance personnel must go to the site from the service center in each district to confirm the cause of the failure. In addition, some faults require the replacement of necessary parts, but maintenance personnel may not carry the parts required to replace the faulty elevator.

Know the cause of the failure in advance and complete the repair in one visit

Not knowing the situation without confirming it on site is the biggest reason for wasting maintenance time and cost. When the customer reports the problem, the description of the fault condition is single, and the customer service staff can only make a rough record. The maintenance personnel must go to the site to find out the cause through a handheld device or laptop connection. After clarifying the countermeasures, they return to the service center in each district to prepare the necessary parts and tools, and then go to the site again for maintenance. Such running back and forth not only creates a workload for maintenance personnel, but also leads to customers' dissatisfaction with the low maintenance efficiency when facing the dilemma of no elevator available.

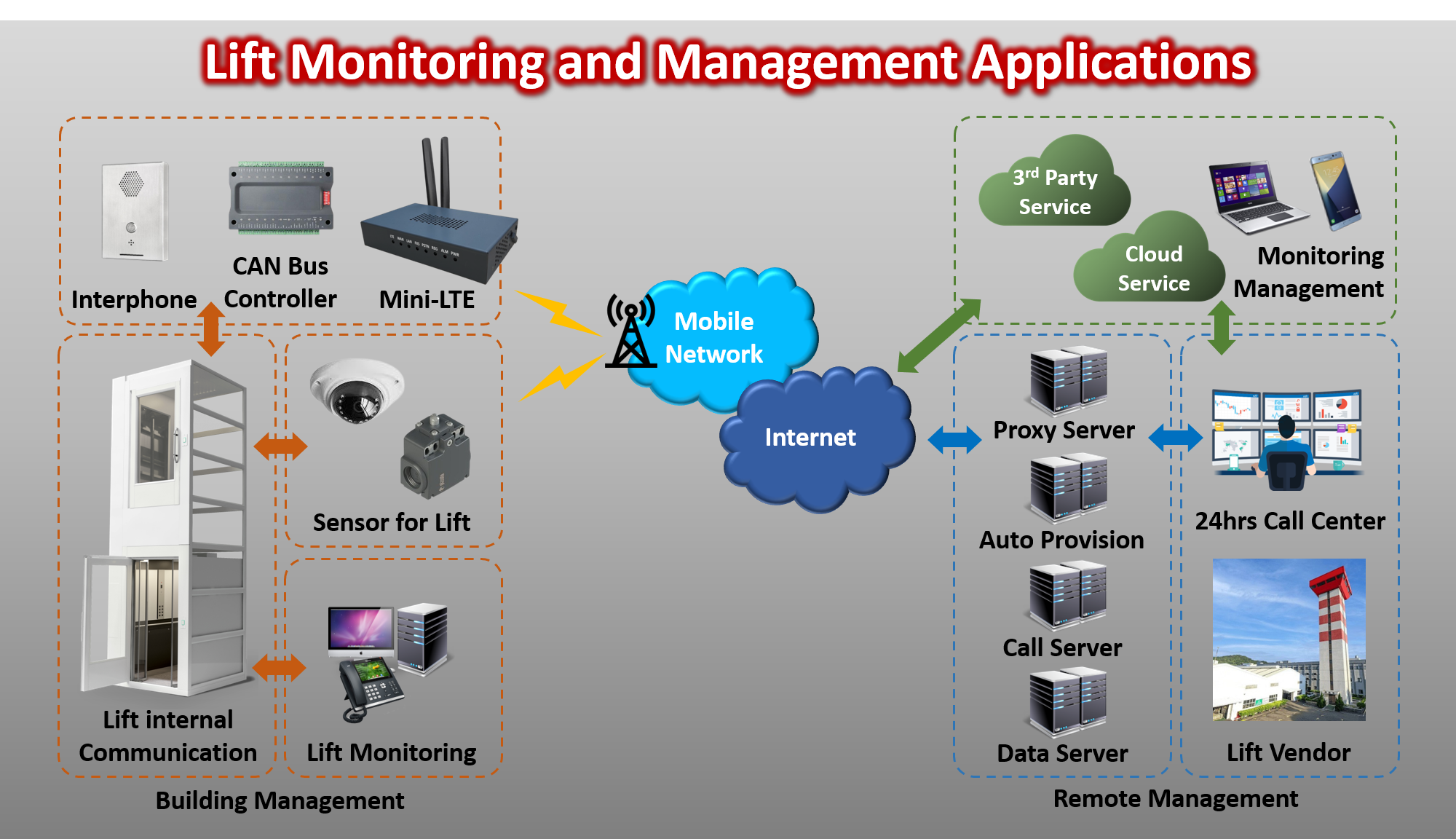

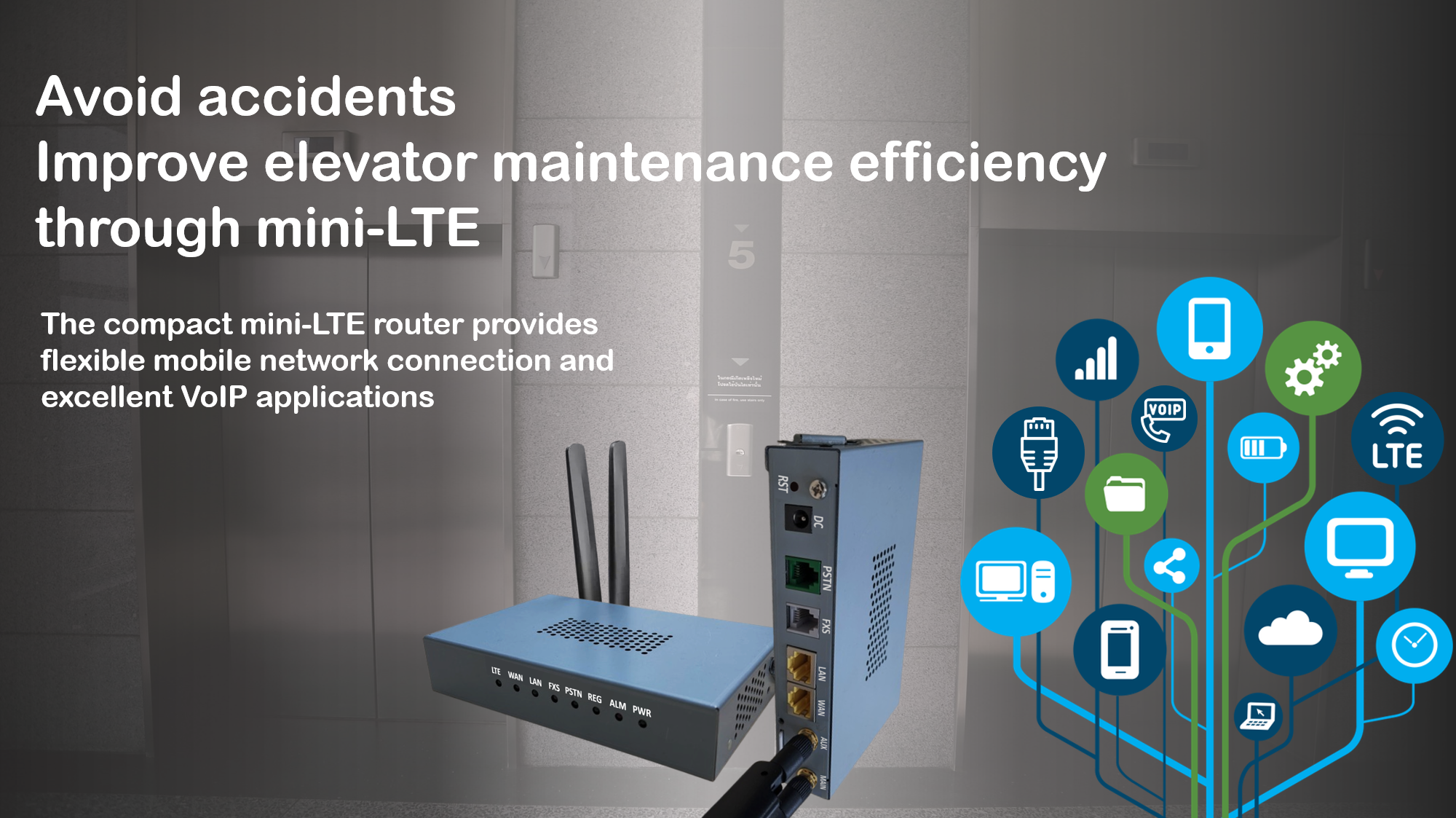

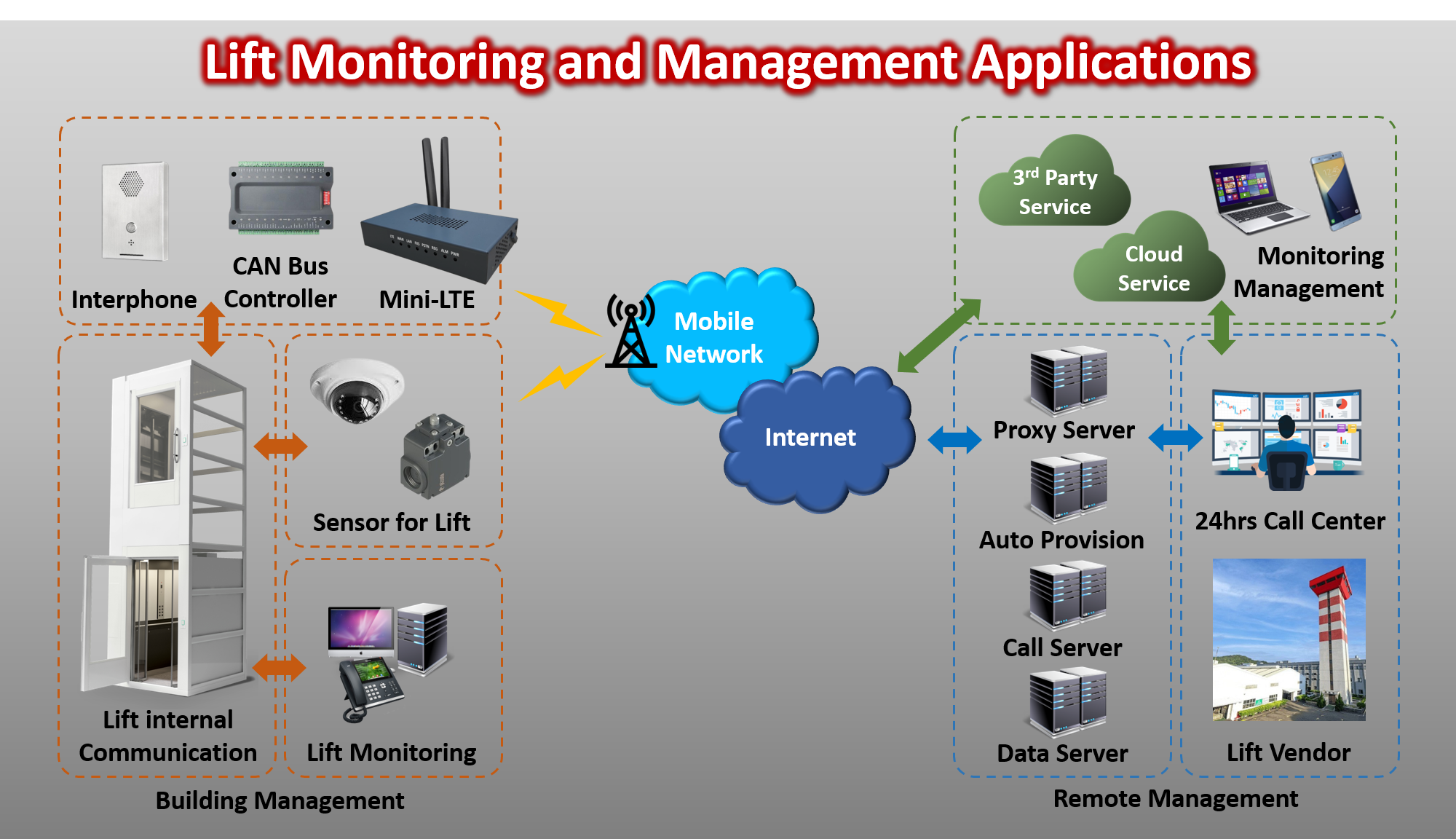

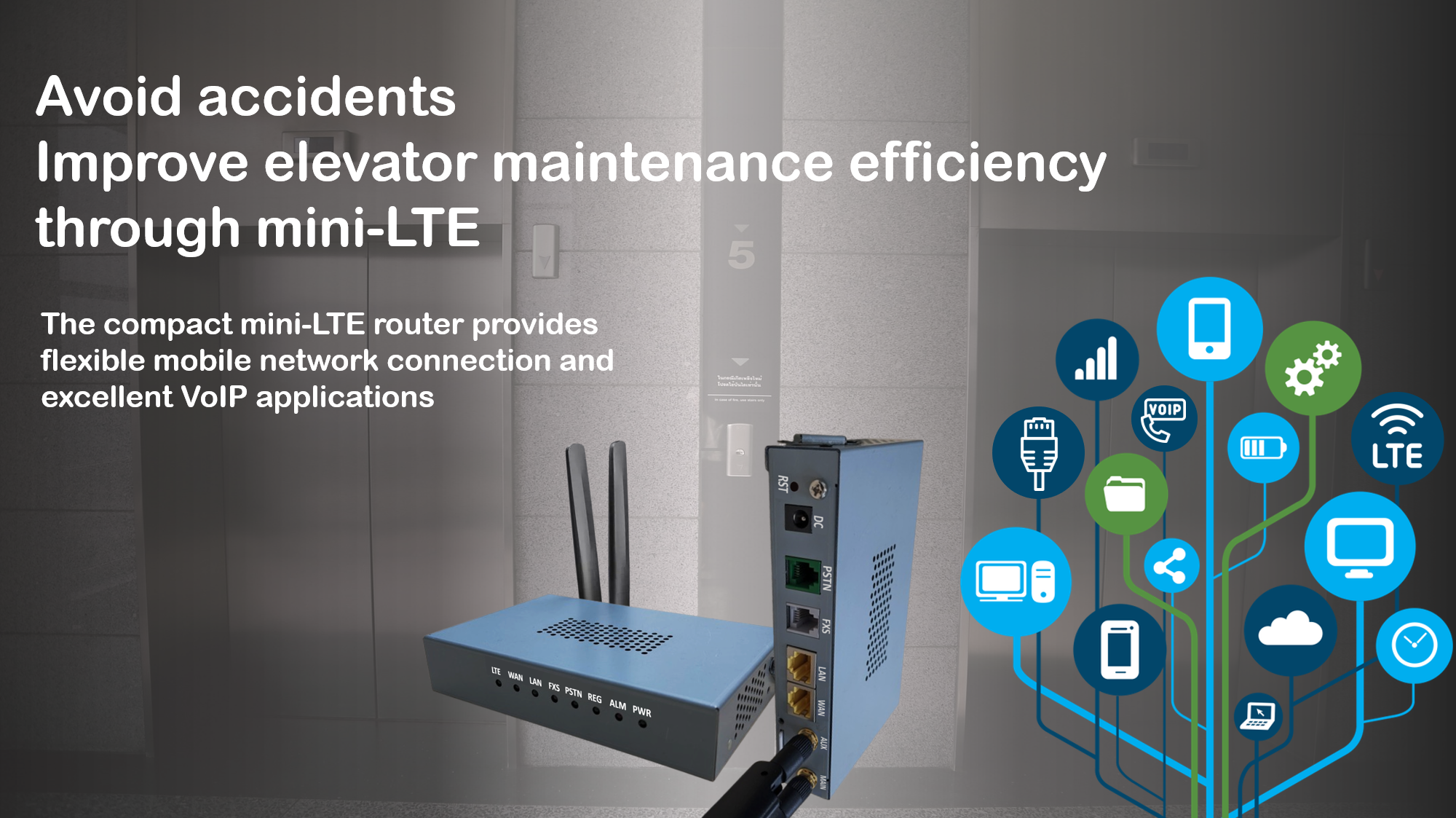

In order to improve maintenance efficiency and customer satisfaction, the most important key is to build a management system that allows maintenance personnel to grasp the elevator information in advance. In order to prepare the necessary parts and tools at the first time, under the original elevator PLC application architecture, maintain high availability and investment cost-effectiveness, introduce LTE communication technology to transmit elevator running data in real time. There is no need to go to the fault site. Maintenance personnel only need to connect to the network to browse the fault elevator status in the service center of each district at the first time.

Regular maintenance of customer satisfaction through remote monitoring prediction

LTE communication technology overcomes the challenge of traditional elevator wiring in basements and buildings. With the support of LTE wireless communication, when any elevator equipment has abnormal running parameters, the remote service center can receive abnormal information and alarms in real time, discover the problem factors in advance, and quickly dispatch workers to troubleshoot or avoid important equipment shutdown.

In addition, maintenance personnel can confirm the cause of the fault in advance and perform predictive maintenance during the monthly scheduled maintenance. Similarly, maintenance personnel can prepare the necessary parts and tools in advance, so that the elevator maintenance work can be carried out more smoothly. The elevator can provide passenger service normally and correctly 24 x 7, improving customer satisfaction with elevator maintenance. In particular, when the elevator is about to expire, and the replacement of the entire motor system and parts and consumables is expensive, a maintenance unit that can prepare in advance and quickly overcome the fault problem will be the first choice for the client or community management committee to sign a maintenance contract.